Maximizing Performance Best Practices From Industrial Gearbox Manufacturers

When you’re looking to maximize the performance of industrial gearboxes, understanding the best practices from top manufacturers can make a significant difference. You might find that selecting the right materials and implementing a solid maintenance schedule are just the beginning. As you explore these strategies, consider how advanced technologies like IoT and AI can further enhance efficiency. But the real question is, what specific steps can you take to ensure your gearboxes not only meet but exceed performance expectations?

Understanding Gearbox Fundamentals

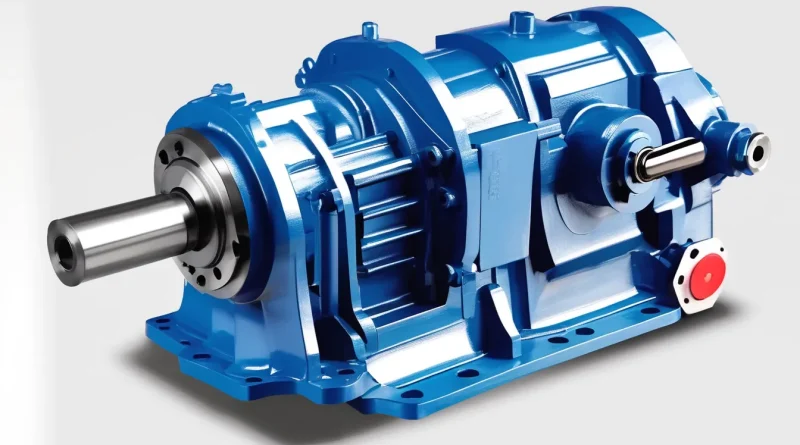

When diving into gearbox fundamentals, it’s essential to grasp the core components that make these machines function effectively. A gearbox typically consists of gears, shafts, bearings, and housings. Each of these elements plays a vital role in ensuring smooth operation and longevity.

Gears are the heart of the gearbox, responsible for transmitting power and torque. They come in various shapes and sizes, like spur, helical, and bevel gears, each designed for specific applications. Shafts connect the gears and transfer motion, while bearings support the shafts and reduce friction, allowing for efficient operation. The housing encases these components, providing protection and structural integrity.

Understanding the gear ratios is crucial, too. They determine how power is transmitted and the output speed of the gearbox. By calculating the input and output speeds, you’ll gain insight into how to optimize performance for your specific application.

It’s also important to consider the operating environment, as factors like temperature and load can impact gearbox performance.

Familiarizing yourself with these fundamentals gives you a solid foundation to build on as you explore best practices for maintenance and operation in the industrial gearbox world.

Selecting the Right Materials

Choosing the right materials for your gearbox can significantly influence its performance and durability.

The materials you select affect not just how well your gearbox operates, but also its lifespan and maintenance needs. Here are three key considerations to keep in mind:

- Strength and Hardness: Opt for materials that can withstand high loads and resist wear. Steel alloys are often preferred for their strength and ability to handle stress.

- Corrosion Resistance: Depending on your operating environment, you might need materials that resist corrosion. Stainless steel or coated components can help prevent degradation over time, ensuring reliability.

- Weight: Lightweight materials can enhance efficiency and reduce energy consumption. Consider using aluminum or composite materials where applicable, but ensure they still meet strength requirements.

Implementing Regular Maintenance

Regular maintenance is crucial for maximizing the lifespan and performance of your industrial gearbox. By scheduling regular check-ups, you can identify issues before they escalate into costly repairs. It’s essential to keep a maintenance log to track activities and findings over time.

Here’s a simple maintenance checklist:

| Maintenance Task | Frequency |

|---|---|

| Lubrication Check | Every 500 hours |

| Visual Inspection | Monthly |

| Filter Replacement | Every 3 months |

Performing these tasks helps ensure that your gearbox operates efficiently. Don’t overlook the importance of cleaning and inspecting the gearbox housing to prevent dust and debris buildup. Also, remember to monitor operating temperatures and vibrations; any anomalies could indicate underlying problems.

Implementing a routine maintenance schedule isn’t just about prolonging the life of your gearbox. It can also enhance overall productivity, minimize downtime, and reduce energy consumption. By investing time in regular maintenance, you’re securing the reliability of your equipment and optimizing its performance. So, make it a priority to keep your gearbox in peak condition!

Optimizing Gearbox Design

Optimizing gearbox design plays a vital role in enhancing performance and efficiency. When you focus on design improvements, you can achieve better reliability and reduced downtime.

Here are three key areas to consider for optimization:

- Material Selection: Choosing the right materials can significantly impact durability and weight. Opt for high-strength alloys that withstand stress while minimizing unnecessary mass.

- Gear Profile: Fine-tuning the gear tooth profile can lead to smoother operation and reduced friction. This adjustment not only enhances efficiency but also prolongs the lifespan of the gearbox.

- Load Distribution: Analyzing and optimizing load distribution across the gears ensures that no single component bears too much stress. This balance can prevent premature wear and failure.

Taking these aspects into account is crucial for maximizing performance. Additionally, you should always assess your design against industry standards and customer needs.

Leveraging Advanced Technologies

In today’s fast-paced industrial landscape, leveraging advanced technologies is essential for gearbox manufacturers aiming to enhance efficiency and performance. By integrating cutting-edge software, automation, and data analytics, you can significantly streamline operations and improve product reliability.

Consider the following table that highlights some key advanced technologies and their benefits:

| Technology | Application | Benefits |

|---|---|---|

| IoT Sensors | Real-time monitoring | Predictive maintenance |

| AI Algorithms | Design optimization | Enhanced performance |

| 3D Printing | Rapid prototyping | Reduced lead times |

| Machine Learning | Quality control | Improved defect detection |

Utilizing these technologies not only helps you stay competitive but also fosters innovation within your organization. For instance, IoT sensors can provide essential data on gearbox performance, enabling you to anticipate failures before they occur. Meanwhile, AI algorithms can optimize designs, ensuring that you produce china gearbox manufacturer es that meet stringent industry standards. By adopting these advanced technologies, you’ll not only improve efficiency but also drive your business toward long-term success. Embrace these innovations, and watch your performance soar.

Conclusion

By embracing these best practices, you can significantly enhance the performance of your industrial gearboxes. Selecting high-strength materials, sticking to a maintenance schedule, optimizing designs, and utilizing advanced technologies are all crucial steps. These strategies not only boost efficiency and durability but also position your operations for long-term success. So, take the initiative to implement these approaches, and you’ll foster innovation and competitiveness in your industry, ensuring your gearboxes deliver top-notch performance for years to come.